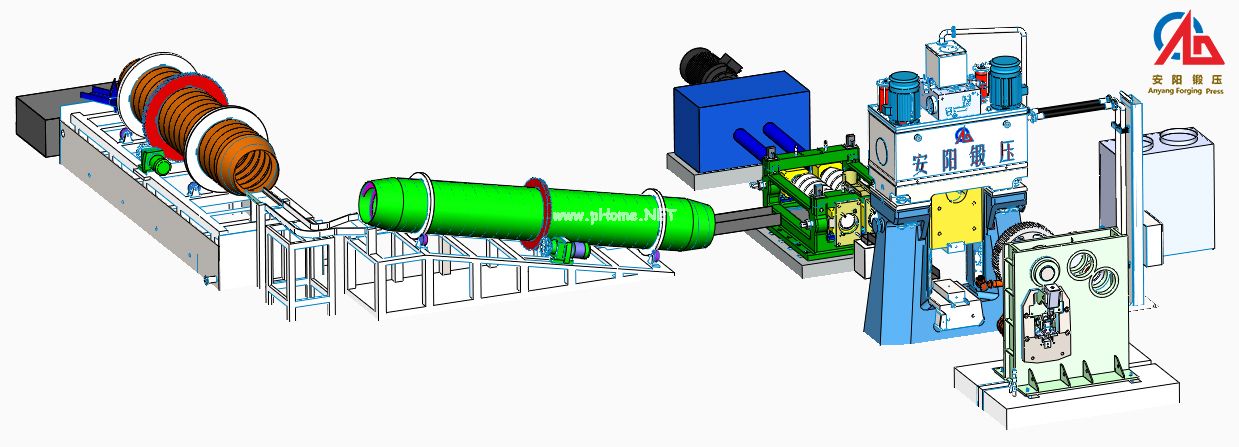

High-efficiency steel ball forging & rolling automatic production line

2018-09-25 11:09:02Steel balls are widely used in mining, steel, chemical, building materials, cement, metallurgy, thermal power plants and other industries. In the past, cast steel balls or forged steel balls were widely used. Although the price of cast steel balls is low, cast steel balls have many disadvantages, such as being easy to wear and fragile; Although the quality of the forged steel ball is very good, the production efficiency is low, so the price is relatively expensive. Therefore, according to the market conditions, Anyang Forging Press Company has specially developed a new steel ball automatic production line that combines the forging and rolling processes - the steel ball forging & rolling automatic production line.

The entire automated steel ball forging and rolling production line includes, medium frequency heating furnace, billet shearing machine, robot arm, CNC forging hammer, rolling machine, quenching machine, tansport device. Anyang Forging Press Company can supply all the equipment needed for the entire automated steel ball forging & rolling line. In February 2018, we export three automatic steel ball automatic production lines to Iran.

Brief introduction of equipment needed for automated steel ball forging & rolling automatic production line:

1. Heating equipment

Anyang Forging Press Company uses medium frequency heating furnace as the main heating equipment for this forging & rolling automatic production line. The intermediate frequency furnace has program control to meet the tempo required for automated production. Compared with gas stoves and other heating equipment, medium frequency furnaces have the characteristics of low noise and high efficiency.

2. Shearing equipment

The Anyang Q42 series bar shearing machine with nominal shear force between 1250 KN and 16000 KN, which meets the shearing work of various types of bar. Moreover, it has a series of automatic functions such as automatic feeding, automatic feeding, automatic length, and automatic cutting.

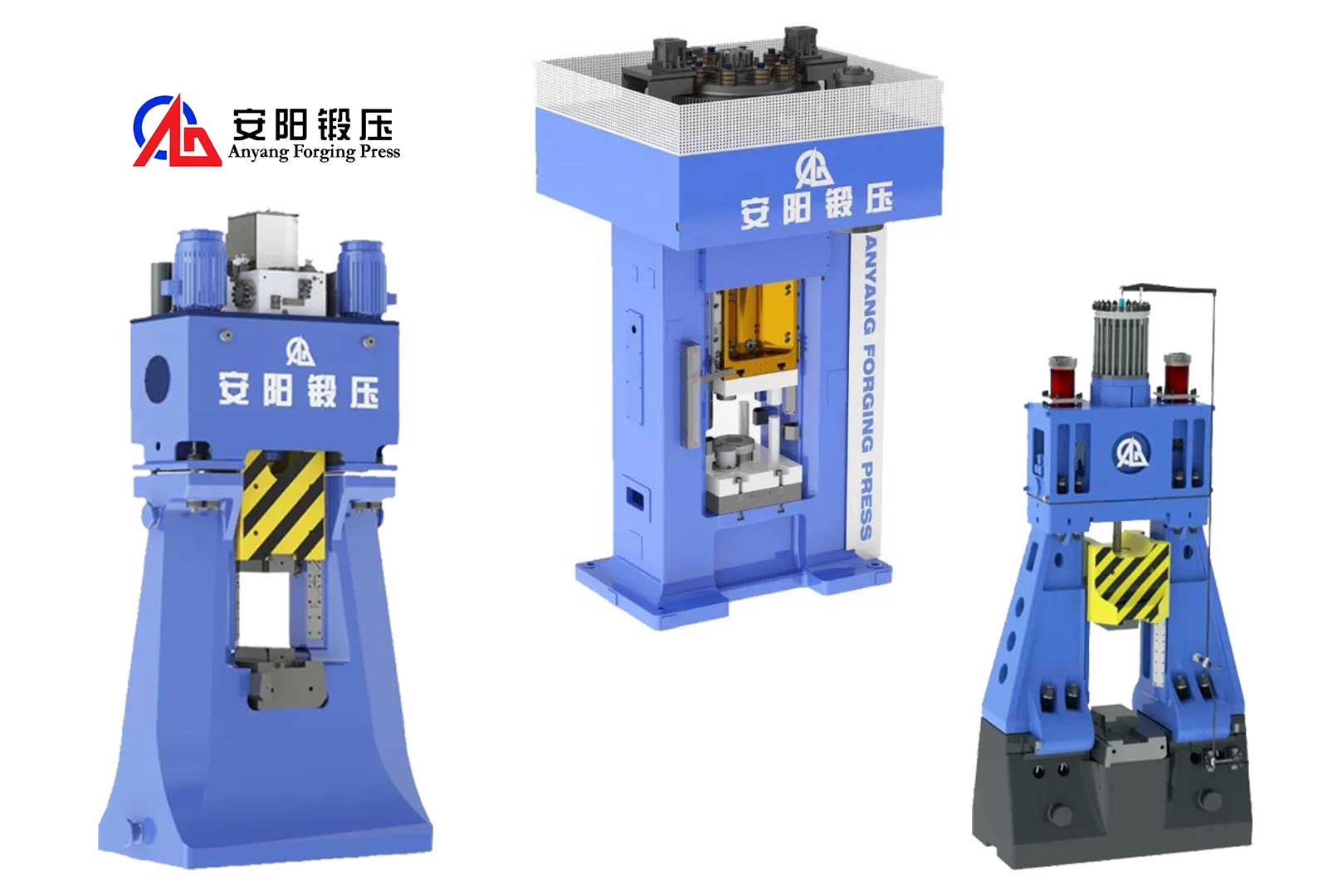

3. CNC forging hammer

Anyang C92K series fully hydraulic closed die forging hammer is with precision program control system, one of the most advanced forging hammers, suitable for all types of precision forging work. Also, CNC hydraulic forging hammer can be used for forging steel balls with high-efficiency. At the same time, for forging steel balls, CNC hammers are easy to automate.

![]()

4. Rolling machine

The roller machine adds special moulds on the basis of the skew rolling mill, the steel ball produced by the CNC forging hammer with a small amount of flashing edge directly enters the rolling machine, and the finished steel ball subjected to the forging process has the characteristics of high-hardness and strong wear resistance.

5. Quenching machine

Our company provides heat treatment equipment that matches the steel ball forging & rolling automatic line. Excellent heat treatment process directly affects the quality of forging & rolling steel balls. Please contact us for specific parameters: michael@chinesehammers.com

6. Conveying equipment

Our company provides reliable conveying equipment, including robot arm and conveyor belt, which ensures the perfect connection of the automatic steel ball forging & rolling automatic production line and further improves the production efficiency of the steel ball.

The steel ball automatic production process is as follows:

First, the billet will be heated by furnace, after that, cut by billet shearing machine in short to the required length, the qualified material is sent to the CNC forging hammer by the robot, the pre-forging "upset ball" scrolls into the rolling machine though the trough under the action of gas cylinder, the rolling machine rolls the "upset ball" into good shape of steel ball, then after the hear treatment, get high hardness of wear-resistant ball.

If you would like you e-brochure on our full range of skew rolling mill, e-mail: michael@chinesehammers.com or call 0086-18625862110 to speak with a PRO.

Welcome to Team Anyang Forging Press.