Connecting rod forging production line

2018-07-21 17:13:37When the connecting rod is working, it not only receives the powerful explosive force of the gas in the cylinder, but also receives the round-trip inertial force and the rotational inertia force. Therefore, selecting a reasonable connecting rod forging process and forging equipment is the premise of ensuring the quality of the connecting rod. The typical production process of the connecting rod is: blanking-heating-roll forge-close die forging-cutting punching-heat treatment-shotting-correction.

1. Cutting

Commonly used cutting methods are: cutting and sawing, Anyang Forging Press Comapny provides billet shearing machine for our customers, we exported our Q42 series billet shearing machine to more than 60 countries.

2. Heating

The recommended medium frequency induction heating furnace has the advantages of improving the working environment, improving the heating quality of the blank and facilitating automated production. The heating temperature affects the intrinsic quality and appearance quality of the forging. The low temperature is beneficial to the strength of the connecting rod and the subsequent heat treatment. However, when the temperature is low, the metal fluidity is poor, the mold wears fast, and when the temperature is too high, the plasticity of the connecting rod is too high. Moreover, the surface oxidation is severe. Therefore, the heating temperature should be maintained at 1200°C ± 50°C.

3. Roll forging

The quality of the roll forging directly affects the quality of the connecting rod. Therefore, attention should be paid to the production process of the connecting rod forging:

①The surface quality of the 1 roll forging die, long-term use, the surface of the die is seriously worn, resulting in the folding of the roll forging blank

② The biting point of each roll forging is inconsistent, and the transition arc is small

③ petals and large and small head transition area appear petal shape

④ blank surface is uneven

Anyang Forging Press Company provides automatic roll forging machine for our customers.

4. Closed die forging

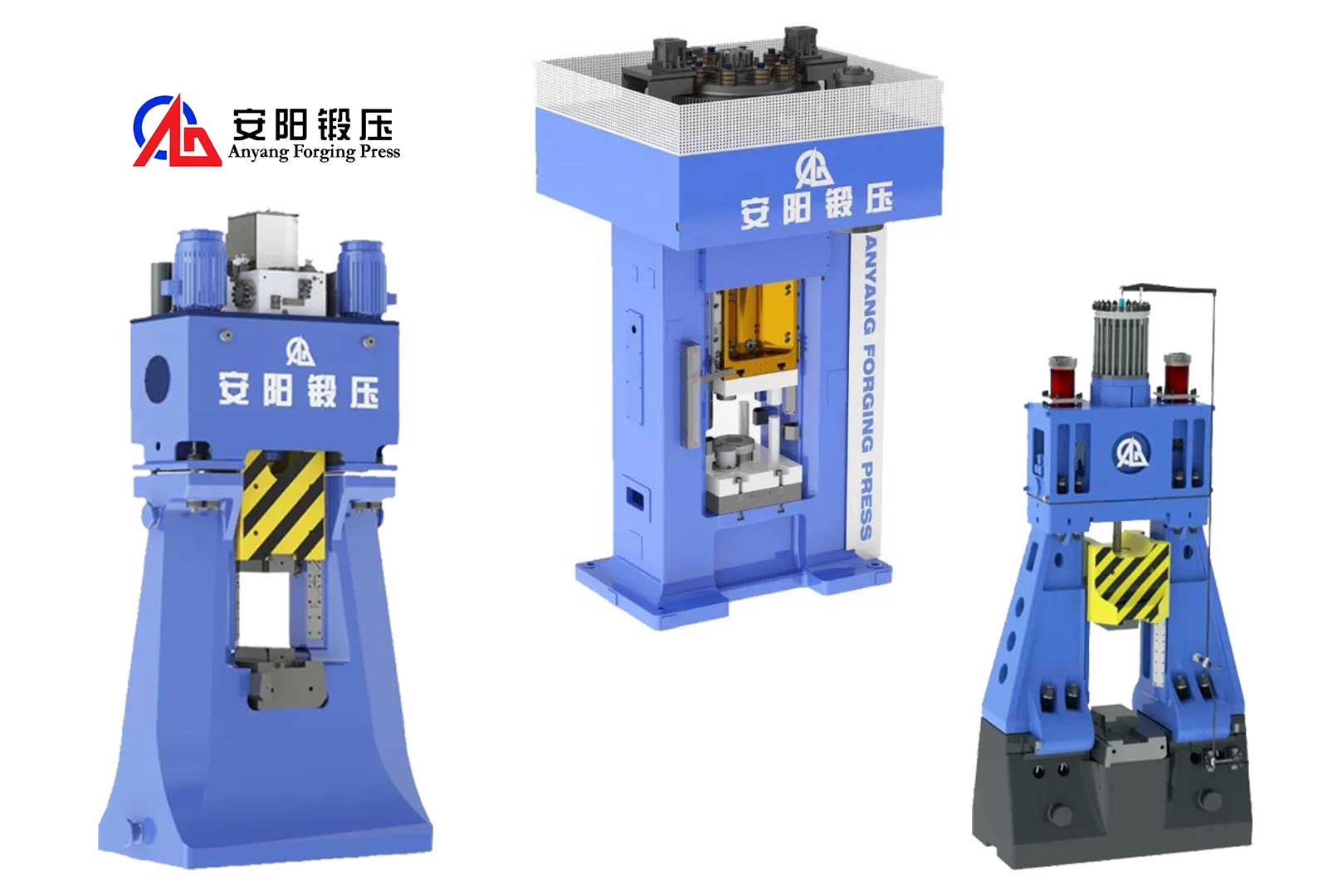

The closed die forging equipment of the connecting rod mainly consists of CNC hydraulic closed die forging hammer, electro-hydraulic hammer, electric screw press, and hot die forging press. Anyang C92K series CNC forging hammer is widely applied in closed die forging works, especially suitable for connecting rod forging works.

5. Trimming and punching

The trimming of the connecting rod is usually carried out in a hot state, and the residual heat after forging is completed in one stroke.

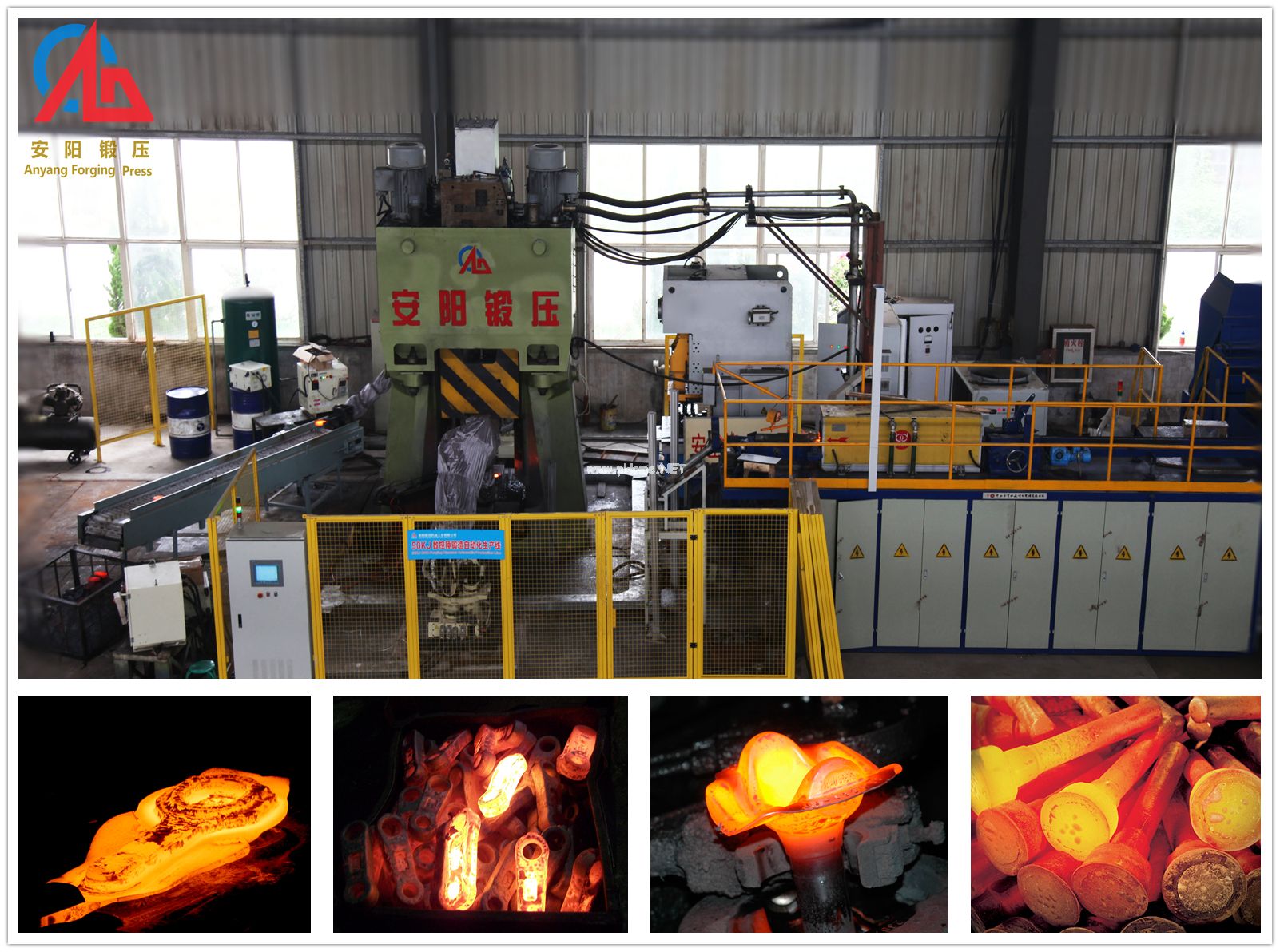

CNC fully hydraulic closed die forging hammer production line

As one of the main equipments for forging of connecting rods, the automatic production line with CNC hammer as the main equipment can realize the continuous production of large quantities of forgings. At the same time, CNC hammers are also precision forging equipment, which guarantees the quality and output of forgings such as connecting rods.

Electro-hydraulic closed die forging hammer production line

Electro-hydraulic hammers are commonly used in die forging production. Their characteristics are wide range of applications, and small equipment can forge large forgings. Our company is able to convert the old hammer into hydrualic forging hammer.

Electric screw press automatic production line

The electric screw press and the CNC forging hammer function are roughly the same, and both are equipped with a high-precision control system, and the forging precision is high. At the same time, the electric screw press has no vibration, no shock absorption, and it is easy to realize fully automated continuous production. In 2017, our company exported to Russia a fully automated production line which makes up by 1600 tons electric screw presses.

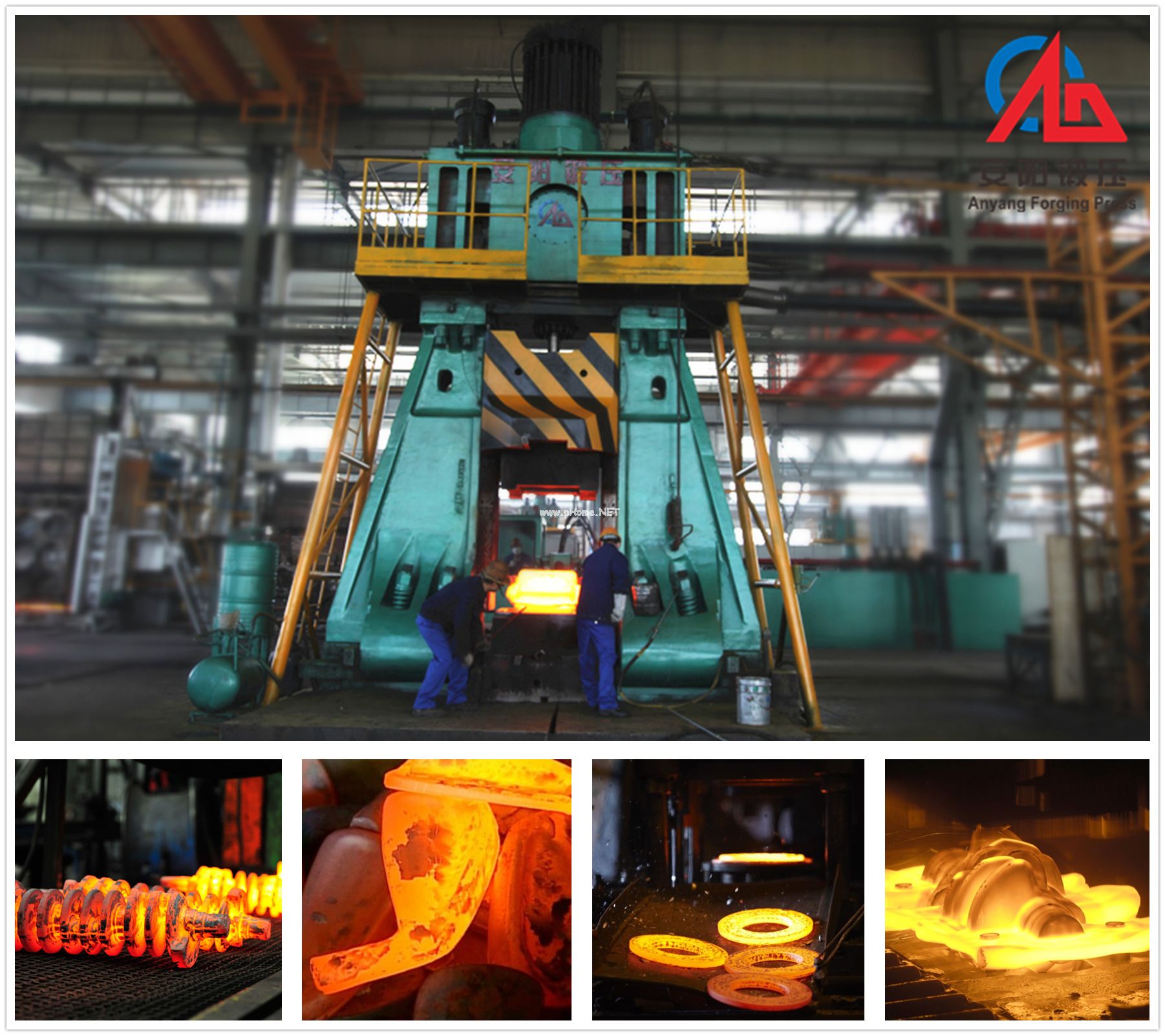

Hot forging press

Compared with the above production lines, the hot forging press production line has a large investment and high output, and customers can select the appropriate production line according to their needs.

Anyang Forging Press Company experience in providing all capacity forging machine for our customers since 1956, if you would like to speak with a PRO, call 86-16692292870 or visit: http://automatic-forging-line.com/

Welcome to Team Anyang Forging Press

Anyang Forging Press Machinery Industry Co., Ltd

Add: West part of Changjiang road, Anyang City, Henan, China

Contact: Felicia Wang

WhatsApp: +86-16692292870

Email: Felicia@anyanghammer.com

Website: http://automatic-forging-line.com/

LinkedIn:

Facebook: https://www.facebook.com/michael.duan.3998

Youtube: https://www.linkedin.com/company/anyang-hammer/