Alloy tool steel forging process & forging machine

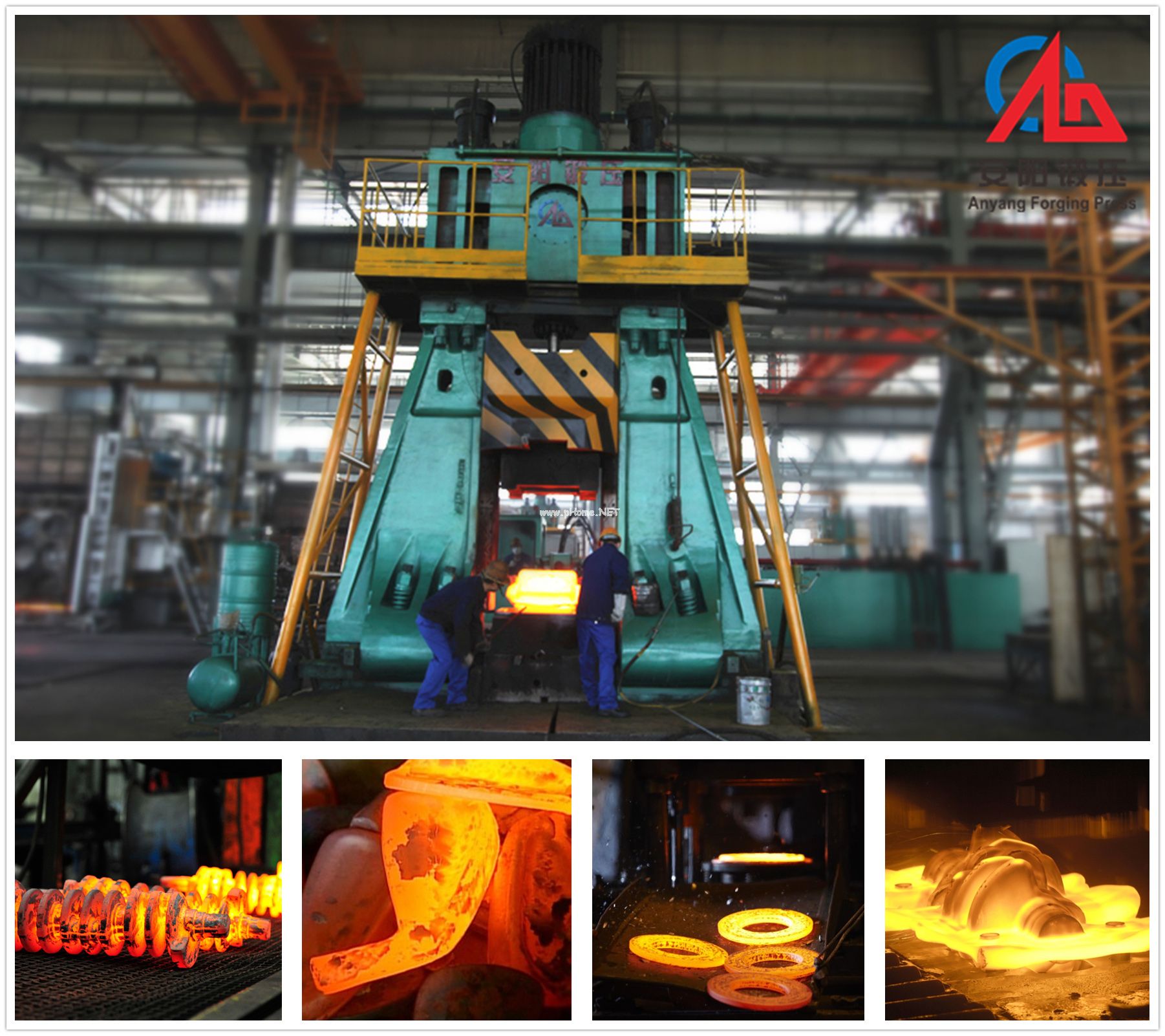

2018-07-12 16:27:39Alloy tool steel is widely used in China, and the most used ones are Cr12, Cr12Mo, Cr12MoV and Cr12V. Because they have a chromium content of up to about 12%, they are often referred to as high chromium tool steels. High-chromium tool steels contain a large number of high-hardness complex carbides composed of alloying elements and carbon. High-alloy complex carbides are difficult to dissolve in austenite and, therefore, cannot be improved by ordinary heat treatment methods. Only with the power of forging equipment can these complex carbides be crushed and evenly distributed throughout the steel interface. The degree of segregation and refinement of complex carbides in the structure of high chromium tool steel has a great influence on the mechanical properties of the mold. In addition, the deformation method, degree of deformation and equipment selection during forging are also one of the key factors.

Alloy tool steel forging process

Degree of deformation: The high-chromium tool steel has a low plastic deformation ability, and its elongation at 1080 ° C is almost 50% smaller than that of the carbon steel at the same temperature. The low plastic deformation ability of high chromium tool steel is particularly remarkable in cast structures that also have Leysite eutectic. Therefore, the ingot must be slightly hammered at the beginning of the forging. Light forging eliminates the dendritic structure of the cast steel and breaks up the carbides distributed along the grain boundaries, and then gradually increases the degree of forging deformation. The forging temperature of high chromium tool steel should not be too high to avoid the risk of excessive oxidation and local melting. High-chromium tool steels have a low deformation temperature, so it is necessary to use forging equipment with sufficient impact energy.

Alloy tool steel forging machine

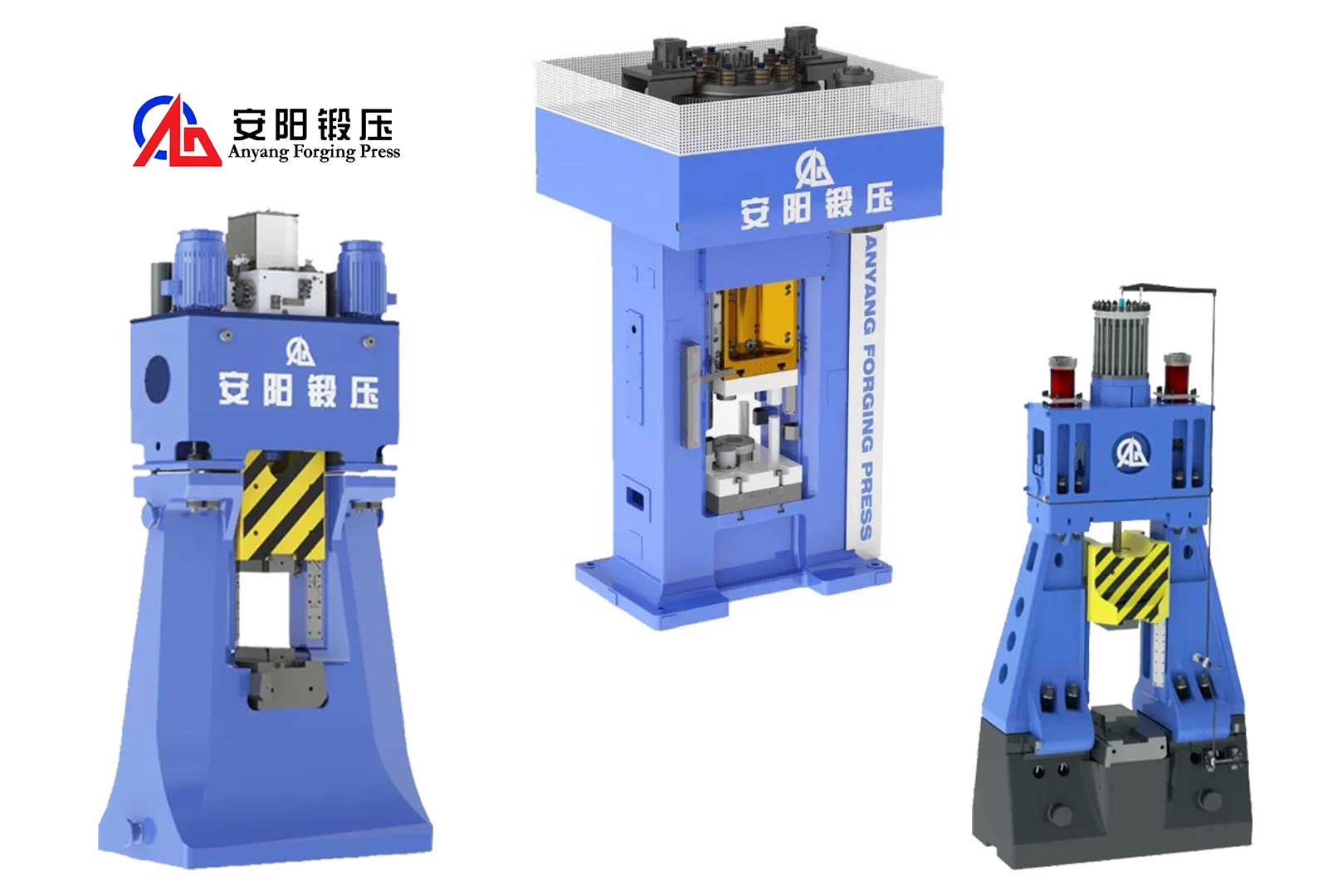

Anyang Forging Press Company experience in manufacture high-quality fully hydraulic forging hammer for our customers. Anyang fully hydraulic forging hammer are widely applied in closed die & open die forging industry. We exported our fully hydraulic forging machine to more than 70 countries. Our main products includes C92K series fully hydraulic CNC closed die forging hammer, C86Y series fully hydraulic closed die forging hammer C66Y series fully hydraulic open die forging hammer etc.

Fully hydraulic forging hammer working process

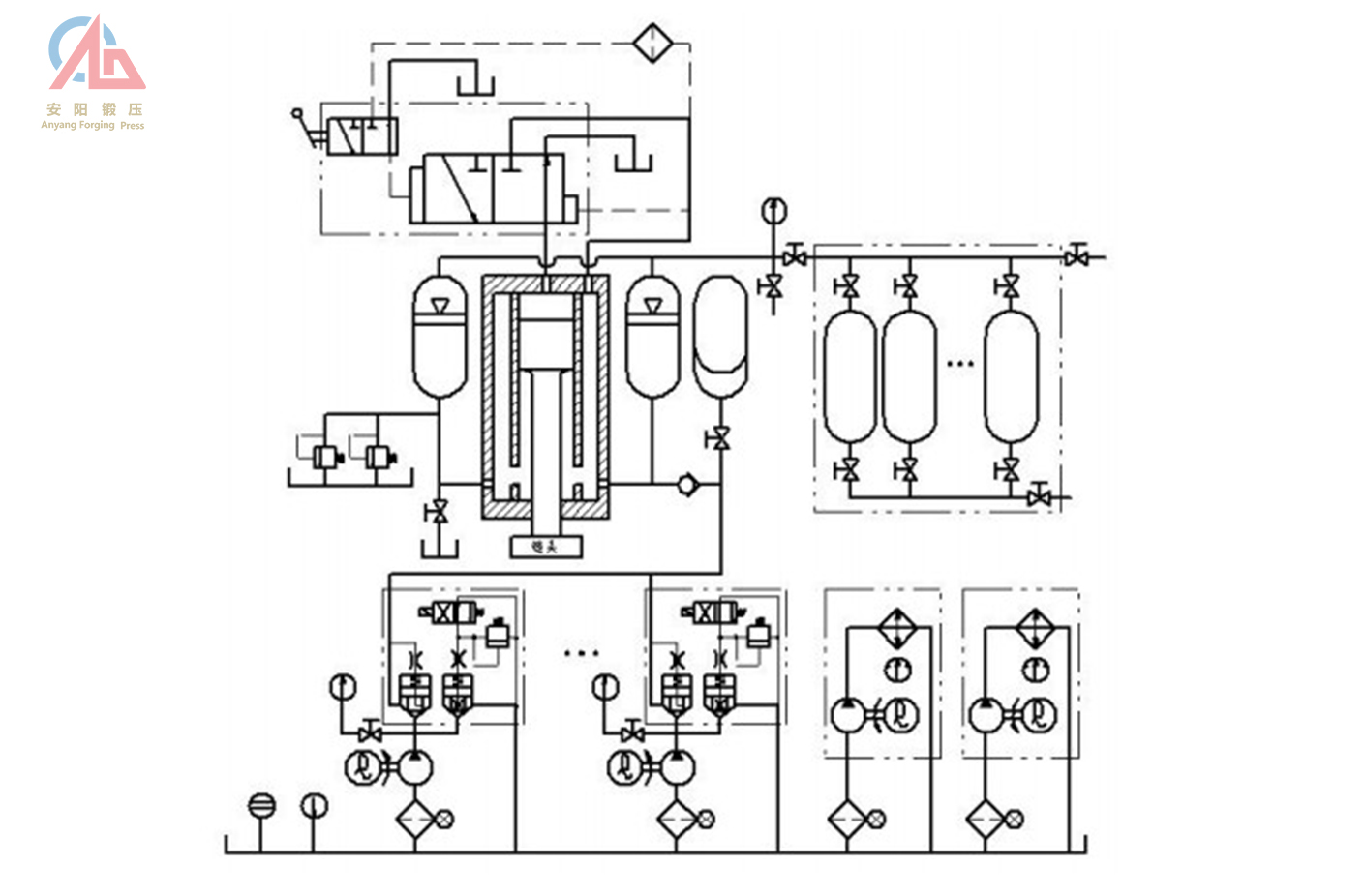

The system principle is that the lower part of the hammer piston is always connected with high-pressure oil, and the high-pressure and low-pressure conversion of the upper chamber oil of the piston is controlled to realize the striking and returning. When the upper chamber of the hammer rod piston passes the high pressure, the lower chamber of the hammer rod piston still passes the high pressure oil, and the high pressure oil that is connected at the same time acts on the circular area of the upper part of the hammer rod piston and the ring area of the lower part, and the downward force is formed due to the difference of the area. And combined with the dead weight of the falling part to achieve a downward strike, while the oil in the lower chamber of the piston returns to the upper chamber of the piston through the connecting oil passage; when the upper chamber of the piston is unloaded to the low pressure, the oil pressure often acts on the area of the lower annular ring of the piston. The return force overcomes the dead weight of the falling part and the corresponding frictional force to achieve the return stroke.

The advantage of fully hydraulic forging hammer

1. The full hydraulic forging hammer is hydraulically driven, so the lifting and striking media of the hammerhead are all hydraulic oil. Compared with the steam-air hammer, the energy efficiency is much higher. The energy consumption of the full hydraulic forging hammer is only 1/40 of the steam hammer of the same tonnage, 1/4 of the air hammer. Moreover, the full hydraulic forging hammer removes the steam power station of the steam hammer, which achieves clean production and saves a lot of water resources; at the same time, fully hydraulic forging hammer avoids the problem of oil and gas exchange.

2. The full hydraulic forging hammer transmission mode adopts the pump-accumulator combined transmission mode, with small installed capacity and high efficiency. The lifting and striking of the full hydraulic forging hammer are jointly supplied by the accumulator and the oil pump. Therefore, the full hydraulic forging hammer lifts the hammer fast, the blow is fast, and the hit frequency is high, which is conducive to the construction of an automatic forging production line with a full hydraulic forging hammer as the main engine.

3. For the full hydraulic free forging hammer, it is easy to flip the forging. For the full hydraulic die forging, it is easy to demould the forging and prolong the service life of the die. When the hammer is lifted, the return only needs to overcome the weight and friction of the falling part, the lifting force is small, the oil pressure is low, the reliability is high, and the service life of the sealing parts is long.

4. The transformation cost is low, the full hydraulic forging hammer makes full use of the original hammer components, and does not change the operation mode. On the one hand, the input is reduced, and on the other hand, the forging process of the original hammer is ensured.

Anyang Forging Press Company is committed to the production and development of forging equipment since 1956, also, we experience in providing turn-key soluions for forging companies including project management for building whole prodution line and facilities.

If you would like to speak with a PRO, call 86-18625862110 or visit: http://automatic-forging-line.com/

Welcome to Team Anyang Forging Press

Email: michael@chinesehammers.com